In 1938, the first electric fence was developed in New Zealand by Gallagher. Since that time, electric fencing systems have made farm and ranch life easier. Today, both permanent and portable electric fencing products are used all over the world.

Basics of Electric Fencing

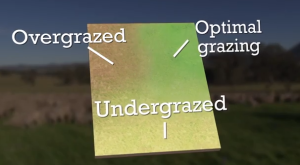

Electric fencing is ideal for grazing or pasture management by containing animals on a selected area of pasture or crop. It also may be used to protect gardens and landscapes from animal damage.

Permanent electric fencing is economical, easy to install and easy to maintain. Temporary electric fencing is an effective temporary barrier for short-term animal control and rotational grazing.

Electric Fencing is...

- Safe: Animals remember the short, sharp but safe shock and develop respect for the fence.

- Easy to install: An electric fence takes less than half the time to build compared to traditional fence systems.

- Durable: A non-electrified fence experiences constant wear and tear under stock pressure. Because your animals learn to avoid an electrified fence, your fence will last longer and remain in good condition.

- Economical: Electric fences cost less than 50% of traditional non-electric fences.

How does an Electric Fence work?

Electric current (AMPS) only flows when a circuit is completed between a positive and negative

terminal.

In this diagram the current cannot flow from the positive terminal to the negative terminal because the switch is open.

In this second diagram, the switch is now closed, allowing the current to flow from the positive terminal through the light bulb (lighting the bulb) to the negative terminal.

An electric fence circuit is made on a larger scale. The energizer fence terminal (positive) is connected to the insulated fence wires, and the energizer earth terminal (negative) is connected to galvanized metal stakes driven into the ground.

The same 'circuit completion' (as in the second diagram) is necessary before the animal gets a shock. An animal standing on the ground and touching the electrified wires will complete the circuit like the closed switch in the second diagram above.

For example, a bird sitting on the wire will not receive a shock. It is not touching the ground so the circuit is not completed. A person wearing insulated footwear will only receive a small shock because all the current cannot pass through the insulated soles.

Dry, sandy or pumice soil is a poor conductor of electric current, so it is a good idea to add an ground (negative) wire into the fence. The animal must touch both a hot wire and ground wire to feel an effective shock.

Choosing the Right Energizer/Fence Charger

Once you have decided what type of electric fence you want for your property, you will need an energizer also known as a fence charger to power it. The correct energizer size for your property is determined by the type of animal to be fenced, distance of fence to be powered and the number of wires in the fence.

There are two types of energizers:

- Mains powered - these are energizer units which are plugged into a mains power supply.

- Battery/Solar powered - these are energizer units which can be left out in your paddock and require a battery to run them. Two batteries can be rotated on a regular basis or a solar panel can be an effective means of continuously charging your battery.

Steps to Good Grounding

Grounding (a.k.a. earthing) is perhaps the most neglected component of many fence systems. We recommend three ground rods, 6’ deep and spaced 10’ apart are the minimum recommendation. Never attach copper to steel. Electrolysis can occur and result in corrosion which weakens shocking power. Use galvanized ground wire and grounding rods to avoid this problem.

Consider that most energizers use galvanized or stainless steel terminals – not copper. Think of your ground system as an antenna that gathers electricity in order to deliver the shock to the animal. Modern satellite receivers can tune in to more television channels than the “rabbit ear” antennas of the past. A hose clamp holding a piece of copper wire to a rusty t-post has been the weakest link of many electric fence systems.